However, when we build the steel pile, we made use of concrete cover around the stack to safeguard it versus longevity problems. Consequently, steel heap building and construction will be done with much treatment. Because of ecological conditions are used for the building. Furthermore, they had good toughness to bring the load of the framework. Whether the heap is socketed or otherwise, we can think about the skin rubbing for the heap style. It is called positive skin friction to withstand the descending motion of the stack.

ANDREW NEIL: America, France, Germany and Poland are ALL piling billions more into defence Browse this site - Daily Mail

ANDREW NEIL: America, France, Germany and Poland are ALL piling billions more into defence.

Posted: Fri, 17 Feb 2023 08:00:00 GMT [source]

The percentages of the pile are dependent upon the dirt kind. Sand is hard to pass through however provides great holding capacity, so the elevation might be as brief as half the size. Clays as well as muds are easy to penetrate but supply bad holding capacity, so the height might be as much as 8 times the size. The open nature of crushed rock means https://writeablog.net/yenianrgwq/these-plastic-piles-have-a-reinforcing-cage-made-of-steel-fiberglass-or-a that water would stream through the ground during installment, causing 'piping' flow.

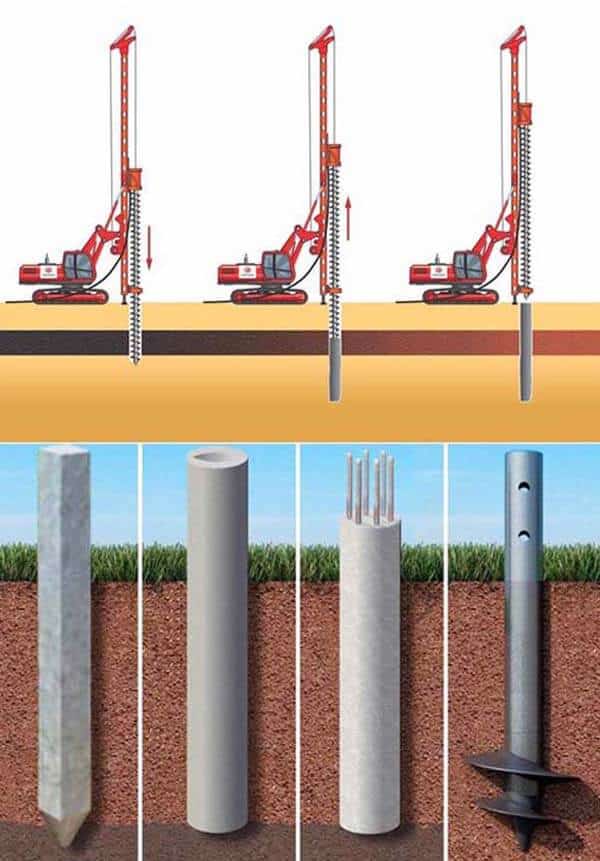

Categories Of Heap Structure

It is obvious from Fig. 16 that the elastic modulus of the heap has little impact on the best uplift bearing capability of the lower uplift stack. When the flexible modulus changes from 3.45 × 104 to 3.35 × 104N/mm2 and also 3.55 × 104N/mm2, the utmost bearing ability of the uplift stack is almost unmodified. The actual stack in the case of this paper was constructed from C50 concrete, with an elastic modulus of 3.45 × 104N/mm2. The flexible modulus of the stack will certainly influence the deformation of the heap and more affect the utmost uplift bearing capability under the very same pile leading variation. The Q-s contours for stacks with different elastic moduli are displayed in Fig. 16.

These stacks are set up at an angle and also are usually used to enhance the slopes. Therefore they are one of the choices for slope security applications. They are additionally great if you have a weak layer of dirt beneath your building.

Mix Rubbing Bearing Heaps

There are two sorts of Kelly Bar utilized, a telescopic Kelly Bar as well as a Rubbing Kelly Bar. To attain the preferred capability, the hammer gear continuously influences the top of the stack. With each strike a reference mark is scribed on the side of the pile.

- End bearing piles are those that obtain most of their tons bearing capacity from the toe of the pile bearing versus the support dirt.

- Lumber heaps that are continuously wet as a result of their place below the ground groundwater level might have an indefinite service life.

- The process of hammering a driven pile into the support soil has multiple benefits.

- Wales are normally positioned on the within face of the wall surface, and also contain 2 networks, back to back, with spacers.

- Generally, the concrete heap is created as rubbing stacks as well as end-bearing heaps.

Stacks can additionally create component of basement wall surfaces as well as shoring systems for huge commercial structure projects. For an in-depth article on cellar kinds and also specifically how heaps create components of cellar walls, have a look at THIS write-up. I have actually had the satisfaction of dealing with Keller on several of my past projects throughout Melbourne.

The strategy can also be made use of on lightly polluted masses as a means of binding contaminants, as opposed to excavating them as well as moving to landfill or handling. A slurry wall surface is an obstacle built under ground using a mix of bentonite and also water to prevent the circulation of groundwater. A trench that would fall down due to the hydraulic pressure in the bordering soil does not collapse as the slurry stabilizes the hydraulic stress. Adfreeze stacks derive their stamina from the bond of the frozen ground around them to the surface area of the stack. Using a tripod rig to install heaps is one of the much more typical means of developing heaps.

What are the two sorts of heaps?

- End bearing heaps transfer tons directly to a deeper strong dirt or rock layer some way listed below the surface.Friction heaps move

- tons by friction in between the surrounding soil and the surface area of the heap over its full length.

Eiffel Trading currently has numerous items of used foundation tools offer for sale, including stack driving devices, pile breakers, casing oscillators, and also a lot more. Pultruded sheet loading is resistant to deterioration, UV degradation, and strikes of aquatic borers and also various other harmful elements. These sheets are also lightweight, which permits easier installation in most cases. Aluminum sheet piling can be made use of in both salt and also fresh water applications, as well as is produced in various sizes, shapes and densities. Responses from the sheeting provide tons on the wales, which serve as beams on supports. The lots on wales ought to include end thrust from various other members in the rate.